Pavers

Clay pavers are a color fast and sustainable material that provides longevity and low maintenance aesthetics to a project. Pavers can vary from heavy vehicular, pedestrian and light traffic to permeable, ADA paving. Natural stone varieties can also be fabricated for flooring to provide ranges of color and finishes to assist in slip resistance and compliance codes.

Sizes

Pedestrian

2 1/4" (W) x 4" (H) x 8" (L)

Vehicular

2 3/4" (W) x 4" (H) x 8" (L)

ADA

4" (H) x 8" (L)

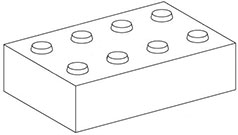

Beveled & Lugged

2 1/4" (W) x 4" (H) x 8" (L)

Permeable

4" (H) x 8" (L)

Need additional sizes? Let us know! We are able to accommodate just about any size and shape for your project.

Get In Touch

Additional Special Sizes

2 1/4" (W) x 8" (H) x 8" (L)

2 1/4" (W) x 4" (H) x 12" (L)

2 1/4" (W) x 3" (H) x 6" (L)

2 1/4" (W) x 6" (H) x 6" (L)

2 1/4" (W) x 6" (H) x 9" (L)

Please contact us to confirm variances in sizes from individual plants.

Colors

Please contact us to confirm specific color varieties from individual plants.

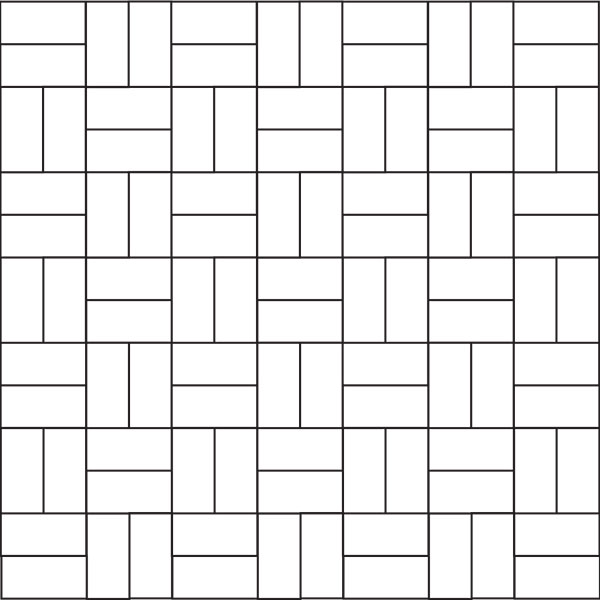

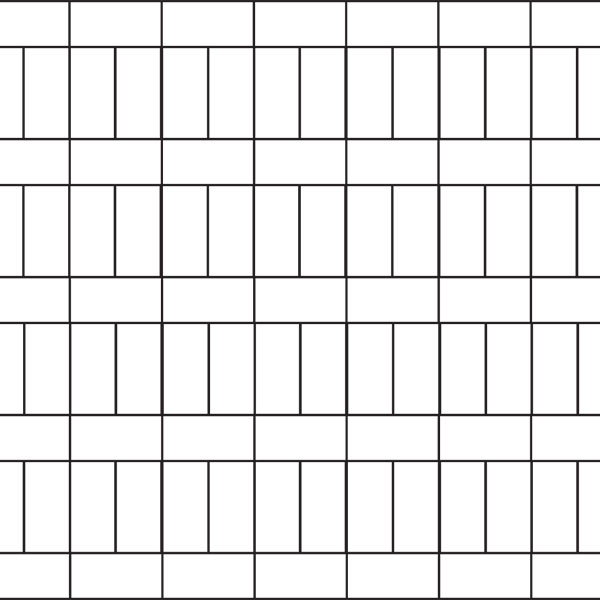

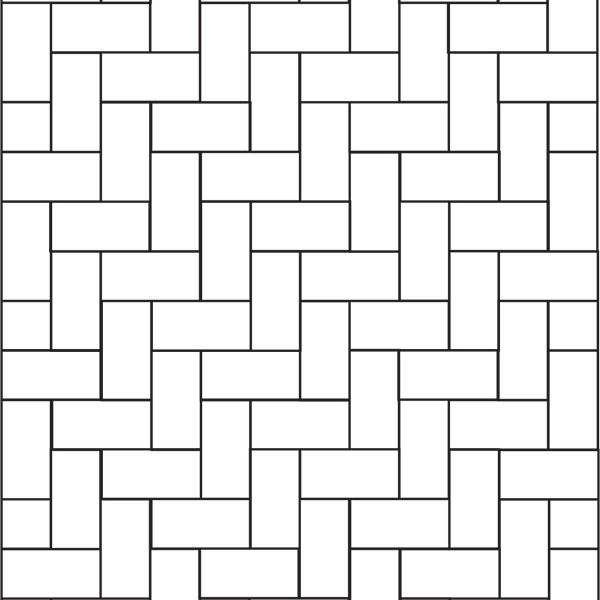

Patterns

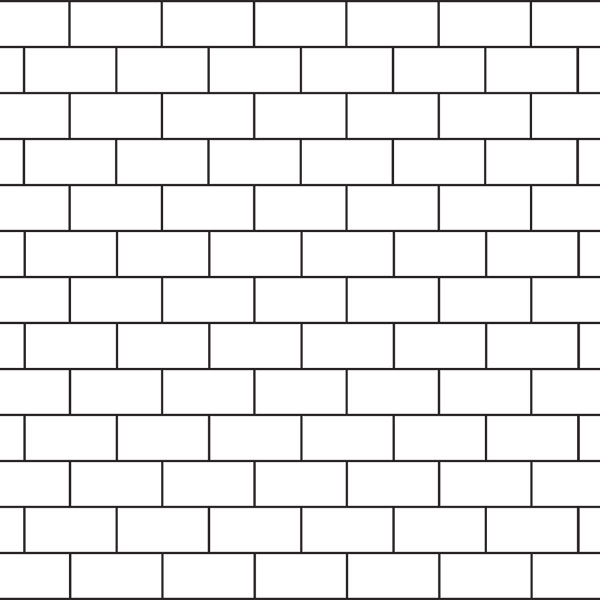

Running Bond

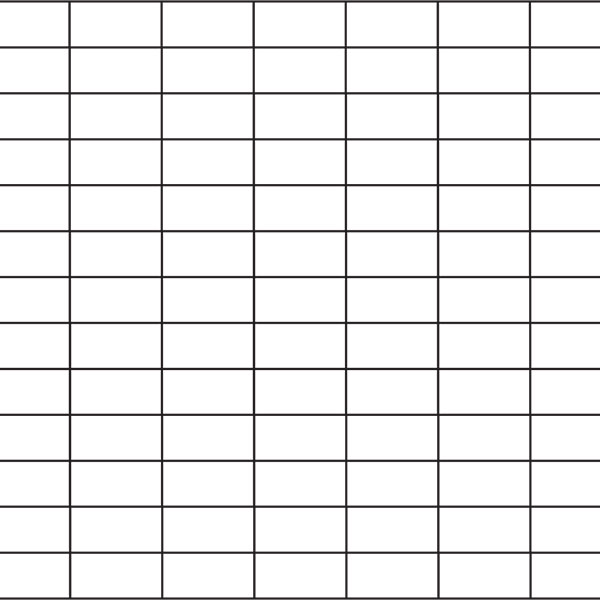

Stack Bond

Spanish Bond

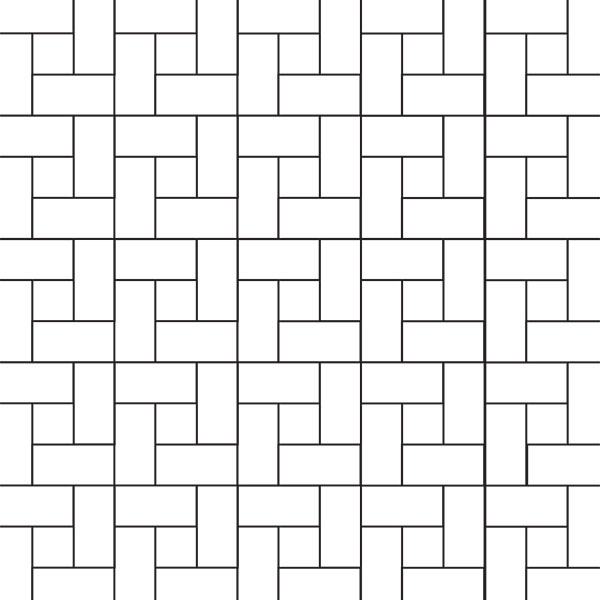

Basket Weave

Single Basket Weave

Herringbone

We are able to accommodate many additional pattern variations, so please contact us regarding specific patterns for your project.

Benefits of Clay vs. Concrete Pavers

Clay pavers are a color-fast installation that last the life of a project. With varying installation systems, clay pavers offer flexibility wearing course. Clay Pavers are made from clay or shale and kiln fired at over 2,000 degrees. This offers a rich color throughout the body of the entire brick that will never fade. Concrete is cured for a surface applied color and concrete aggregate in the body of the paver that may fade as early as 6 months after installation due to UV exposure.

Cost savings are found over time with little to no maintenance, no fading and high density which eliminate chippage and cracking. The density of clay pavers allows for no absorption. Concrete pavers absorb water and other particles in the air which often lead to mold and efflorescing.

| Clay Pavers | Concrete Pavers | |

|---|---|---|

| Compressive Strength | > 26,000 psi | 8,000 psi |

| Water Absorption | < 3% | 5% Maximum |

| Freeze/Thaw Durability | Excellent | Average |

| Abrasion Resistance | Excellent | Good |

| Color Retention | Excellent | Poor |

| Efflorescence | None | Common |

| Stain Resistance | Excellent | Poor |

| Maintenance | None | Sealing Recommended |

| Life Span | 100+ Years | 10 to 20 Years |

| Sustainability | Excellent | Average |

Pedestrian and Light Vehicular vs. Heavy Vehicular

There are two specifications for clay paving brick. ASTM C902 outlines the requirements for Pedestrian and Light Traffic paving brick and ASTM C1272 covers brick pavers for Heavy Vehicular Traffic uses.

Pedestrian ASTM C902

-

This paver is intended for use in pedestrian applications and vehicular areas that are subject to low volumes of vehicular traffic

- Driveways such as passenger drop offs

- Pedestrian sidewalks

-

Classifications

-

Weather

- Class SX — Brick intended for use where brick may be frozen while saturated with water.

- Class MX — Brick intended for exterior use where resistance to freezing is not a factor.

- Class NX — Brick not intended for exterior use but which may be acceptable for interior use where protected from freezing when wet.

-

Traffic

- Type I — Brick subject to extensive abrasion such as sidewalks or driveways.

- Type II — Brick subjected to intermediate abrasion such as heavily traveled sidewalks and driveways.

- Type III — Brick subjected to low abrasion such as floors or patios in residential homes.

-

Weather

-

Technical Requirements

- 8000 psi requirement

- Brick pavers shall be free of cracks or other imperfections detracting from the appearance of a designated sample when viewed from a distance of 15 feet for Application PX and a distance of 20 feet for Application PS.

Heavy Vehicular ASTM C1272

-

This paver is intended high volumes of heavy vehicles with 3 or more loaded axels or 251+ daily single axis loads.

- Streets

- Commercial Driveways

- Aircraft Taxis

-

Classifications

- Type R — Brick intended to be set in mortar or asphalt

- Type F — Brick intended to be set in sand

-

Application

- PS — Pavers intended for general use.

- PX — Pavers intended for use where dimensional tolerances, warpage, and chippage are limited.

- PA — Pavers intended to produce characteristic architectural effects resulting from nonuniformity in size, color, and texture.

-

Technical Requirements

- 8,000 psi for pavers set on a concrete or bituminous bed (Type R) or 10,000 psi for pavers set on a sand bed (Type F) minimum thickness depending on the application:

- For pavers set on a bituminous or rigid setting bed (Type R) pavers must be at least 2 ¼ inches thick

- For pavers set on a sand setting bed (Type F) pavers must be at least 2 5/8 inches thick

- Brick pavers shall be free of cracks or other imperfections detracting from the appearance of a designated sample when viewed from a distance of 15 feet for Application PX and a distance of 20 feet for Application PS.

- 8,000 psi for pavers set on a concrete or bituminous bed (Type R) or 10,000 psi for pavers set on a sand bed (Type F) minimum thickness depending on the application:

Efflorescence & Cleaning

Efflorescence occurs when clay pavers absorb water containing soluble salts. The salts get left behind on the paver surface when the water evaporates. The salt source typically stems from the water rather than the paver itself. The most common source for salts in a paving system is deicing salts or newly poured concrete. Other factors include aggregates, sands, screenings and soft water. Screenings made from limestone contain carbonate that often cause efflorescence. The best way to remedy efflorescence is to avoid using materials that contain soluble salts.

For additional cleaning instructions please visit AHI Supply.

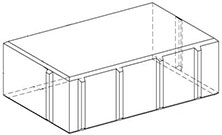

Permeable Pavers

Permeable pavements are made with clay pavers on an aggregate setting bed, an open-graded aggregate base, and an open-graded subbase. This paving system offers environmental protection and storm water management. Permeable clay pavers are an effective method of meeting stringent stormwater management requirements. The use of permeable clay brick pavements has shown to be cost- effective in new development and redevelopment since such pavements reduce or eliminate the need for storm sewers and detention ponds, while providing more land for buildings and other structures.

Some form of stormwater management is required in almost any contemporary development. In developments with impervious pavements, stormwater management consists of inlets, culverts, swales, retention ponds and detention basins, and the land to place those items on. Permeable pavement is a completely different approach in which stormwater is absorbed into pavement that is built as part of the development. Because permeable pavement effectively manages stormwater, it reduces or eliminates the need for specialized stormwater facilities.

Benefits

- Permeable clay brick pavements aid in the health of street trees by allowing air and water to reach the roots easily.

- Permeable pavements do not increase the temperature of the runoff, minimizing the damage to aquatic life.

- Permeable paving has a low runoff coefficient, which is the percentage of the total rainfall that will become runoff.

- Water quality improves as oil from vehicles, the most generic pollutant originating on city pavements, is dissipated. Oil that enters through the surface clings to the aggregate particles. It then migrates slowly down and has an extended residence time in the pavement structure. Naturally occurring microorganisms ingest the oil and biodegrade it, thereby reducing the oil’s hydrocarbons to their simpler chemical constituents.

- Exfiltration of water from the base and subbase reservoir into the subgrade soil reduces the total volume of runoff, eases the loads on city sewers and stream channels, further improves water quality in the soil, and replenishes groundwater aquifers with clean water.

The highly permeable aggregate that fills the joints is what gives the pavement surface as a whole its permeability, rather than the shape of the paver. In permeable pavements, spacers (lugs on clay pavers are larger to maintain a uniform joint width of 1/4 in. or wider. In contrast, pavements made with a sand setting bed have sand- filled joints as narrow as 1/16 in. The joint fill aggregate for permeable pavements is open-graded for high permeability, with particles small enough to fit into the paver joints but large enough to meet filter criteria with the underlying setting bed aggregate. The aggregate is commonly specified to be washed free of clinging particles. It is swept into the paver joints and openings, and the pavers are vibrated to level. The joints must not be left unfilled. One of the purposes of the aggregate is to trap sediment and debris near the pavement surface, where it can be removed by vacuuming.

The key process for maintaining a permeable pavement is vacuuming. Sediment accumulates mostly in the uppermost 1 in. of joint aggregate, where it is accessible by vacuum suction. Vacuuming lifts sediment out and restores the pores to their original open condition.

For more information, please view the Brick Industry Association’s technical note on Permeable Clay Brick.