Thin Brick

Thin veneer masonry continues to grow in popularity. Certain projects require expedited timelines, budget constraints and structural limitations making thin brick an ideal building solution. Thin veneer is often used in interiors due to quick, easy and less costly installation. For projects with expedited production timelines, thin brick can be tile set in tilt wall applications. New doors have been opened in renovation projects where thin brick is used to alter the appearance of an existing structure.

Sizes

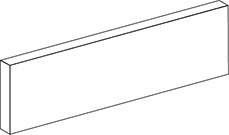

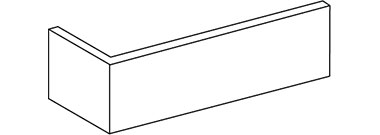

Flats

Modular

1/2" (W) x 2 1/4" (H) x 7 5/8" (L)

King Size

1/2" (W) x 2 5/8" (H) x 9 5/8" (L)

Roman

1/2" (W) x 1 5/8" (H) x 11 5/8" (L)

Norman

1/2" (W) x 2 1/4" (H) x 11 5/8" (L)

Utility

1/2" (W) x 3 5/8" (H) x 11 5/8" (L)

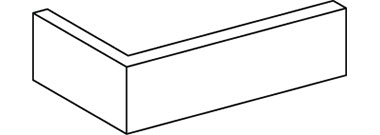

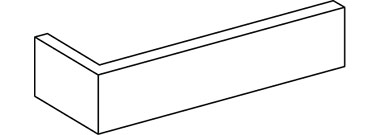

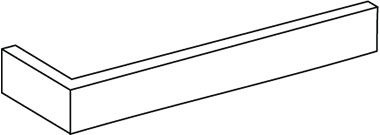

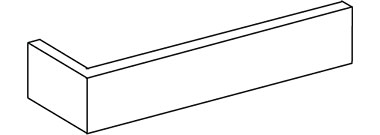

Corners

Modular

1/2" (W) x 2 1/4" (H) x 7 5/8" (L)

King Size

1/2" (W) x 2 5/8" (H) x 9 5/8" (L)

Roman

1/2" (W) x 1 5/8" (H) x 11 5/8" (L)

Norman

1/2" (W) x 2 1/4" (H) x 11 5/8" (L)

Utility

1/2" (W) x 3 5/8" (H) x 11 5/8" (L)

Need additional sizes? Let us know! We are able to accommodate just about any size and shape for your project.

Get In Touch

Please contact us to confirm variances in sizes from individual plants.

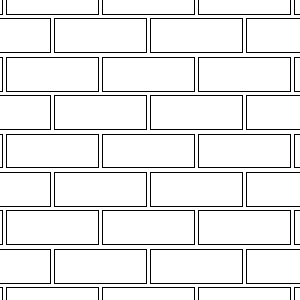

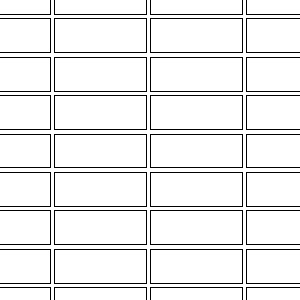

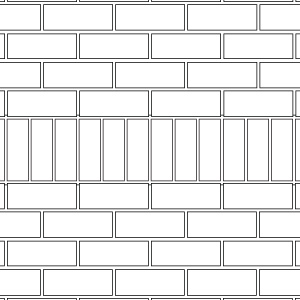

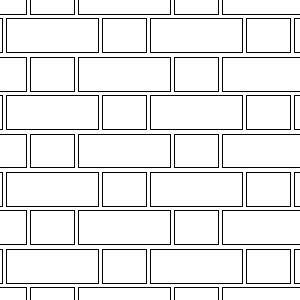

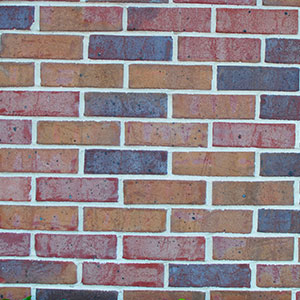

Patterns

Running Bond

Stack Bond

Soldier Course

Flemish Bond

We are able to accommodate many additional pattern variations, so please contact us regarding specific patterns for your project.

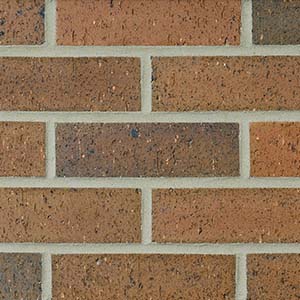

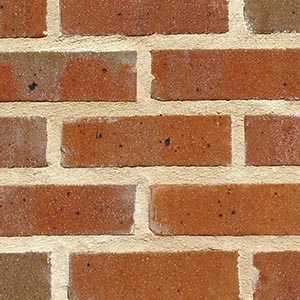

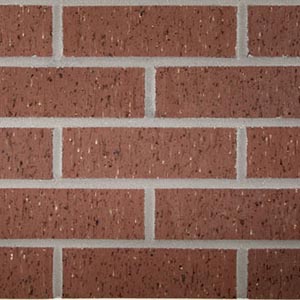

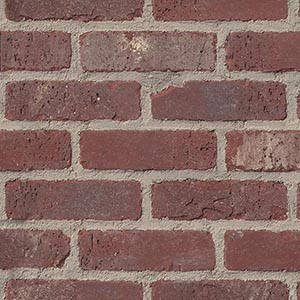

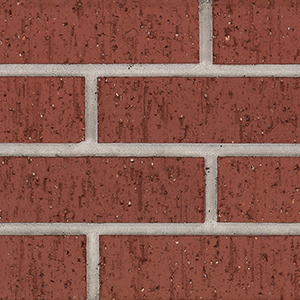

Colors & Textures

Velour

Smooth

Vertical Scratch

Papercut

Distressed

Tumbled

Access and download our full color catalog on the software downloads page.

Software Downloads

Please contact us to confirm specific color and texture varieties from individual plants.

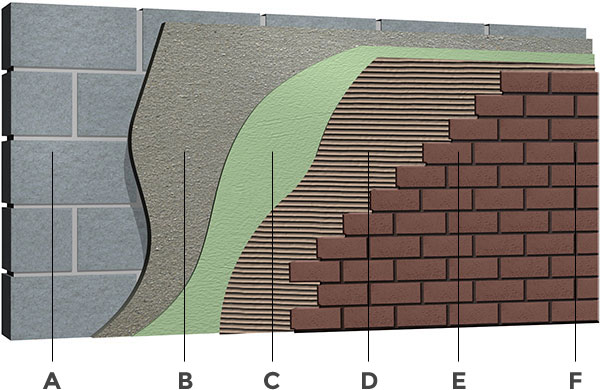

Installation

Legend

- Concrete or Masonry

- Laticrete Premium Mortar/Leveling Bed

- Laticrete Air and Water Barrier

- Laticrete Masonry Veneer Mortar

- Masonry Veneer

- Laticrete Masonry Pointing Mortar

TBS vs. TBX

According to ASTM C1088, Thin Brick Standard and Thin Brick Excellence refer to dimensional tolerances permitted in brick. This coding does not have to do with the unit's durability but rather the unit's mechanical tolerances. Type TBX Brick is intended for general use in exterior and interior walls where a high degree of mechanical perfection, narrow color range, and minimal variation in size is permitted. TBS units indicate standard production and offer a wider range of color and size tolerances. Type TBA units are used to create special architectural effects. These units have no limits for size and color variations.

Dimensional Tolerances

Variations in raw materials and the manufacturing process will result in brick that vary in size. Permitted size variation is based on the brick classification and the relative dimensional range measured. Size variation becomes important when vertical alignment of brick (stack bond) is used, when bands of brick from different production runs are combined, or when a short horizontal extent of brickwork is constructed, such as between closely spaced window openings.

Distortion

Distortion or warpage may be convex or concave and may be in the plane of the wall or perpendicular to it. Other terms for distortion are “bowed” or “banana” brick. A brick that is over the distortion limitations is difficult to lay and is easily noticeable in the brickwork

Chippage

Brick may be damaged or chipped during packaging, shipping or on the job site. A delivery of brick may contain up to 5% broken brick or brick chipped beyond the limits. Chips are measured from an edge or a corner, and the total length of these chips may not be greater than 10 percent of the perimeter of the face of the brick.

TBX allows:

- Waste — Up to 10% (includes excess chippage)

- Chips — 1/8” edge, 1/4” corner

- Cracks — any not seen from 15 feet away

- Size Variation — 5/16” from each other

- Warpage — 1/16” for under 8” dimension

TBS allows:

- Waste — Up to 20% (includes excess chippage)

- Chips — 5/16” edge, 1/2” corner

- Cracks — any not seen from 20 feet away

- Size Variation — 1/2” from each other

- Warpage — 3/32” for under 8” dimension

For more information, please view the Brick Industry Association's technical notes on brick specifications and classification.

Severe Weather vs. Moderate Weather

The weather classification assigned to a brick is based on physical properties of the brick. They determine durability based on the severity of weather and the exposure of the brick. Because of the varying climates and applications of brick, specific physical properties are required.

There are two accepted methods for demonstrating durability under ASTM standards:

- durability as predicted by compressive strength, absorption, and saturation coefficient, or

- durability as determined by compressive strength and passing 50 cycles of the freeze and thaw test.

For durability classifications the letters S, M and N in C 62, C 216, C 652 and C 902 indicate the following exposure conditions:

- S indicates severe weathering

- M indicates moderate weathering

- N indicates negligible or no weathering

Type SW or SX, meet the designation for the most severe weathering exposure. Some manufacturers produce brick complying only with the designation for moderate weathering, MW or MX. Grade NW or NX brick are typically confined to interior applications, or where they are protected from water absorption and freezing.

For more information, please view the Brick Industry Association's technical notes on brick construction.